Biomaterials can be divided into four categories: polymer, ceramic, metal, and composites.

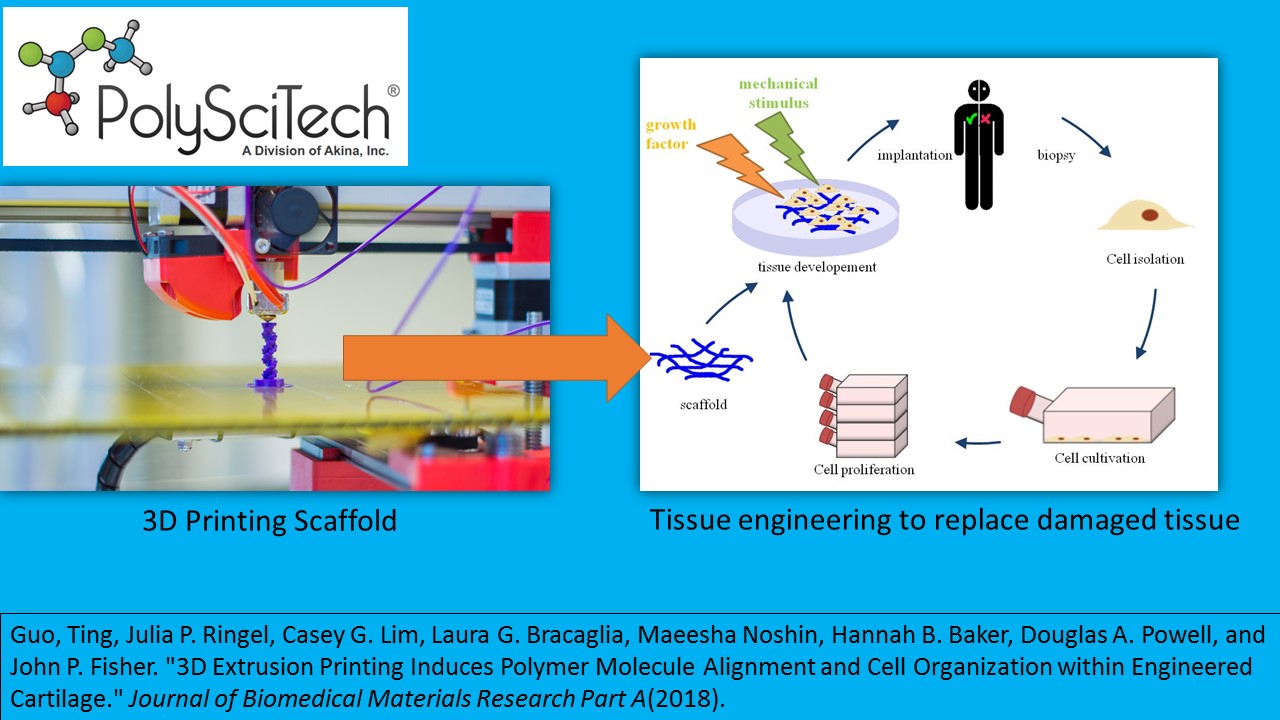

Many conventional fabrication methods including thermally induced phase separation, emulsion freeze-drying, solvent casting, gas forming, and electrospinning have been studied and developed, but 3D printing is more suitable for bone tissue engineering because of its ability to manufacture complicated structures. Moreover, scaffold structures such as porosity, pore size, and pore shape should be optimized to achieve cell viability and proliferation. Scaffolds are required to have non-hazardous properties such as biocompatibility and biodegradability for the human body, and the necessary mechanical properties to support body weight, or to perform other roles, depending on the type of tissue. This paper reviews the scaffold design considerations, manufacturing methods, and biomaterials for bone tissue engineering, and discusses current challenges and future perspectives. Scaffold fabrications and biomaterial selections are crucial factors for artificial tissue and bone tissue engineering, which are important due to the limited availability of tissue donors. In order to obtain.The goal of tissue engineering is to replace or regenerate damaged tissue. However, PCL has its disadvantages: being a hydrophobic polymer, it shows poor cell adhesion and low surface energy. Polycaprolactone (PCL) is a biodegradable polyester which has good biocompatibility, mechanical properties and minimal inflammatory reactions and is certified by the US Food and Drug Administration (FDA). Currently, many researchers tend to blend the natural polymers and the synthetic polymers in order to improve mechanical, physical, and chemical properties of the scaffolds. However, a disadvantage with the natural polymers is the low mechanical strength. Compared with the control group, HepG 2 cell grows well in the collagen/silk nanofiber scaffold and maintained the functions in longer time. HepG 2 cells can be seeded on the scaffold. have fabricated a collagen/silk nanofiber scaffold through electrospinning. The natural polymers have good biocompatibility and nontoxicity and thus are suitable for cell adherence and growth. These reports indicated that both the natural and synthetic polymer scaffolds could be fabricated by using electrospinning, and these scaffolds have been used in liver tissue engineering. Recently, Chu and co-workers have demonstrated that a conductive nanofiber scaffold, polypyrrole/poly(lactic-co-glycolic) acid (PLGA), also has the potential application as a suitable substratum for hepatocyte culturing in liver tissue engineering. have reported for the first time that an electrospinning chitosan nanofiber scaffold could enhance cell attachment, improve liver functions of hepatocytes, and exhibit better viability than the controls. To date, some efforts have been made to study the application of nanofiber scaffolds in the hepatocyte in vitro culture. Electrospun nanofiber scaffolds have been successfully applied in bone, skin, nerve, blood vessel, and even liver engineering. The electrospinning is a convenient and versatile technique to fabricate nanofibers scaffolds for tissue engineering applications. The nanofibers are regarded as the promising scaffold that can be used to mimic the architecture of ECM. Therefore, many researchers have proposed the three-dimensional (3D) microenvironments that mimic the normal in vivo extracellular matrix (ECM) in order to promote cell adherence and growth. Hepatocytes in two-dimensional (2D) culture systems tend to lose their differentiated functions and exhibit poor viability.

The development of hepatocyte culture system is an ongoing topic. However, it remains a question how the hepatocyte culture in vitro can maintain the differentiated phenotype, functions and viability of hepatocytes long-termly. (2) International Cooperation Laboratory on Signal Transduction, Eastern Hepatobiliary Surgery Hospital, The Second Military Medical University, 0000 0004 0369 1660, grid.73113.37,, 200438, Shanghai, Chinaīioartificial livers (BAL), which contain a cellular component, vital hepatocytes in bioreactors, have been proposed as a promising extracorporeal temporary livers for patients awaiting liver transplantation to treat acute liver failure. (1) State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University, 0000 0004 1755 6355,, , 201620, Shanghai, China Author(s): Yujie Qiao 1, Xuelong Liu 1, Gongbu Fu 2, Zhongyuan He 1, Chengyi Hou 1, Yaogang Li 1, Qinghong Zhang 1, Hexin Yan 2, Hongzhi Wang 1

0 kommentar(er)

0 kommentar(er)